All that stuff about moulded pulp

2024-03-15 16:36

In recent years, with the implementation of the upgraded version of the "plastic limit order", the establishment of the "double carbon" goal, and the continuous strengthening of consumers' environmental awareness, the demand for green packaging in many industries has continued to grow, and new alternatives to pulp molding products have quietly become popular.

And with the continuous progress of intelligent equipment technology, pulp molding process has made rapid progress, the birth of a large number of application scenarios, triggered the boom of paper and plastic manufacturing industry

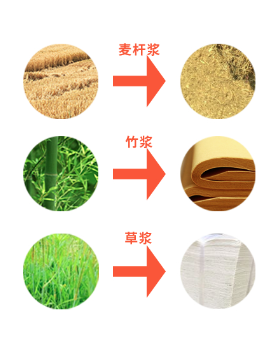

Pulp molding products are using fully recycled plant fiber pulp (bamboo, sugarcane pulp, etc.) or waste paper recycled pulp as the base material, using unique technology, made of a kind of pollution-free scientific and technological green products widely used in food (medicine) storage, electrical packaging, planting and breeding seedlings, medical utensils, handicrafts bottom blank and fragile product liner packaging and other fields.

Pulp molding products as a new green products, wide application prospects, not only used in catering, food, electronics, electrical appliances, computers, mechanical parts, industrial instruments, but also used in crafts glass, ceramics, toys, medicine, decoration and other industries, its application value has been more and more fully demonstrated.

The biggest highlight is derived from natural fibers, return to nature completely does not pollute the environment, become a natural organic part. Truly come from nature, return to nature, the whole life cycle does not pollute the environment, completely in line with the concept of environmental protection, for the green mountains is Jinshan Yinshan.

According to the use scenario of pulp molding products can be divided into four major uses: agricultural packaging, food packaging, industrial packaging and medical product packaging.

Get the latest price? We'll respond as soon as possible(within 12 hours)