- Home

- >

- News

- >

- Pulp molding process

- >

Pulp molding process

2024-03-15 16:41

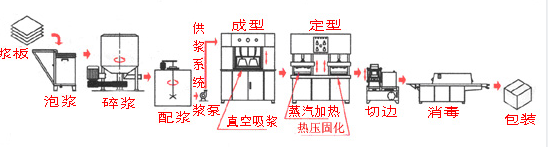

Pulp molding (plant fiber molding) products pulping process is the use of pulp cardboard, waste paper, cartons, etc. as raw materials, through pulp crushing, grinding and other processes, so that paper into fiber, suspended in water to form paper slurry. Then the paper slurry is adsorbed in a special mold to form a wet blank, and the finished product is formed through hot press drying, cutting and other processes.

With the improvement of people's living standards and the enhancement of environmental awareness, it is also accompanied by the continuous improvement and promotion of pulp molding products process technology, and the application scenarios of pulp molding products are more and more extensive. It is because the pulp molding (plant fiber molding) products have sufficient raw material sources, the production and use process is pollution-free, a wide range of application, low cost, light weight, high strength, plasticity, cushioning, interchangeability, good decoration performance, can be repeatedly used and recycled and other characteristics, so it has a strong vitality and broad application prospects.

Get the latest price? We'll respond as soon as possible(within 12 hours)